Table Saw Machines For Sale Australia

Table Saw Machines For Sale Australia

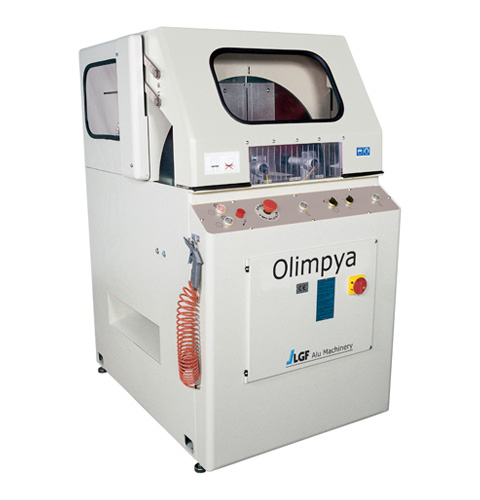

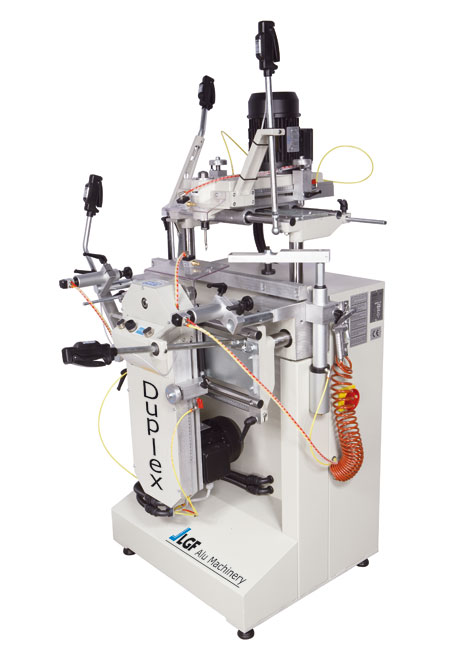

Quality Table Saws For Sale – Australia Wide Delivery

Whether it is a DIY project for your home or a business requirement, we understand your needs and provide you with the right table saw to suit your purpose.

MMVIC is a prominent name in the woodworking industry in Australia. We offer Laguna timber table saws and most other brands for sale at the competitive rates. All of our table saws are made with updated technology and are of high-quality. Regardless of the type of material that you are looking to saw i.e. softwood or hard one, you are certain to find the right table saw for your project.

Our Range of Laguna Table Saw Machines

We specialise in supplying large industrial timber table saws for sale that deliver the highest quality cuts and meet the high industry standards.

Our Service and Maintenance of Table Saw Machines

The available table saws for sale in Melbourne is backed up by a proper maintenance system with the presence of all the necessary supplies. Our skilled and experienced team ensures that your machinery is running at its peak efficiency, making you highly productive.

Explore Our Timber Table Saws for Sale Today

Explore our website for Table saws for sale in Melbourne. If you have any questions, feel free to call us at (03) 9720 1678.

We have thousands of woodworking tools, machinery, accessories, and hand tools to choose from in store or online – we’ve got every job covered and the price range that meets your budget.

For the best advice talk to any of our team members or call Dean directly 03 9720 1678 for technical advice and get unbiased, expert advice. every time. The MMVic showroom is located in Bayswater Melbourne and offers extensive product information and demonstrations on machinery & equipment

Shop Online – Delivery Australia Wide.